|

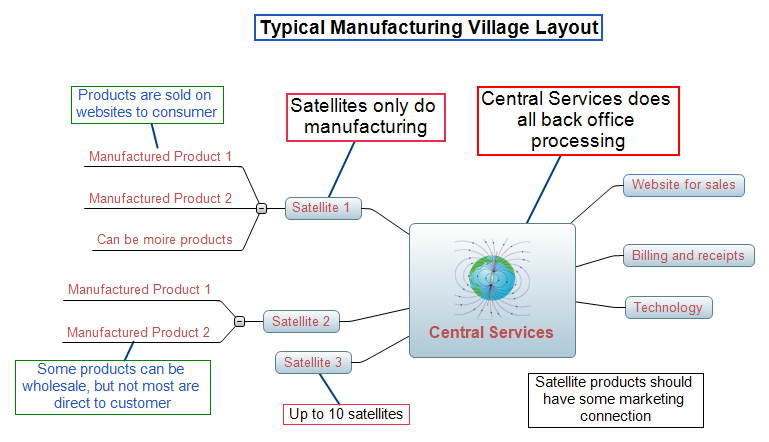

Philosophical Reasons for Manufacturing Villages - mouseover titles below for more information |

-

Satellite - 95% Success Rate

The reason for most failures in small business is lack of structure. Central Services eliminates this issue: the satellite can focus on production, not endless back office tasks.

- Central Services also makes sure the satellite has the proper technology installed for maximum production efficiency.

- Central Services creates and manages the sales, vast majority being customized products sold direct to the consumer over the internet

- Central Services monitors the accounting allowing for continuous monitoring to catch anomalies

- Satellites must run an environment/culture allowing employees to feel free to contribute to the company's success

- Constant review of operations including monitoring of production machinery for maintenance

- Owners of satellite production companies are tested for ability to see everything and get upset if things are not done correctly.

This all ads up to a 95% success rate making raising local capital easy through crowd fundraising. In fact, I expect the investors to drive to the facilities and give advice (good or bad), sort of like a super-board of directors.

-

Living Company Environment

Shifting from merely earning a living, the 21st Century finds working environment a critical issue to success, particularly in small manufacturing businesses - ok, so I'm only concerned with manufacturing, the rest of you take care of yourselves. Read more about enjoying your work life...

Since every writer is convinced the work environment/culture starts at the top, we will make sure the psychological profile of the owner understands real people work at real jobs: This expands to work is not so separate from the triazls and tribulations of trying to have a family, starting a family, and actually having children.

The order of business for the satellite owner and central services franchiser is a buy-in of the emmployees in the rules. If everyone agrees how to make up for an off-day or more for an employee, people will feel a responsibility not to abuse the rules.

One of my rules, which I consider important, is prople not staying past 6 pm- even the owner. Running through the internal energy of people results in lower productivity and lower quality. Worker longer does not translate to worker smarter.

Hiring people with time to learn what they need for their future position is a great idea.

Holding meeting where everyone must contribute to the meeting - that is, everyone is heard and their contribution respected - keeps people on the same goals and feeling their contributions make them feel important.

I will try to do some interviews and if finding a good article on environment I will add that here.

-

Never Lose a Website

One of the greatest fears of a small business? Losing the "webmaster". Even before that, finding a person or company able to express the "gut" of the business can be amost fearful process. Central Services saves the day! Even if the web designer of an individual MV leaves, the national organization takes up the slack until a new local person is installed. The national level creates forms and questionaires leading to a template leading to presenting either just information or, since we sell directly to the consumer, a really fabulous ecommerce site.

-

Entrepreneur Profile

If everyone was a capable manufacturer life would be easier. Manufacturing Villages need to be selective of people with the GOOD gut feel: They must not only have a great desire to build, but additionally, a history of making something/anything.

Were you the one who fixed your friends' bicycles? Did you have a power drill that fell apart from use? Were you the yearbook photographer and did some of the darkroom work? (Yes, I'm old enough to remember using an enlarger and chemical to produce photos of the sports people who bought the photos.)

Are you reliable? Since you will be the boss we can't have you coming in late and leaving early. If your employees need something done will you see it is done.

And nothing passes your eagle eyes. No detail is too small if something is not right.

I have been assured psychological tests can filter out the people who only talk and find the doers.

-

Growing bigger

We'll have an entire area in Central Services to transform satellite producers grown too big for a Manufacturing Village to transform into an independent company. Many of the services run by Central Services will be run by a separate company dedicated to larger businesses.

-

Investment - Central Services and Satellites

Central Services, set up as a franchise for quality control purposes, is funded from select investment funds who believe in the manufacturing villages concept. In the long-term, 100% ownership by the Manufacturing Villages is necessary for sustainability. Rarely does the quality of investor reach beyond the original investor. This cannot be allowed to happen to the project. Sorry, but you will earn a proper profit for your investment. Time to go on to other investments.

Individual satellite manufacturing operations are funded in three ways: 1. The entrepreneur has enough wealth to do the entire investment, 2. Crowd funding through our internal program for an individual satellite, and 3. From a mortgage style fund used to invest in satellites. All satellite investment is local money and, moreover, the profits stay in the community.

Central Services, set up as a franchise for quality control purposes, is funded in the begginning from select investment funds who believe in the manufacturing villages concept.

Raising money for the satellites is really easy as local investors, not only assured of a 95+% success rate - remember central services is watching.

I haven't forgotten all the issues with, say, just keeping the investments within the local community or changes in entrepreneurs. These are not simple issues and have never been addressed anywhere before. We will create a legal structure appropriate to modern manufacturing. Who knows, the legal structures we develop could be a profit center.

-

Mass Customization - a MV Advantage

I'm stating very explicitly here: Manufacturing Villages are about customization of products for the direct customer. Whether apparel, jewelry, or even garden decorative products, customization using modern technology allows the production of individualized products. Being small manufacturers allows customization a larger company usually trips over its own processes. Read the customized explanation ...

Here's a very direct example of customization. An office worker or executive wants something for warmth (women complain about how office temperatures are set for men wearing jackets), fits them correctly, is easy to take care of, and looks business like. With automated knitting machines the order, with not only style and color choices but also many dimensions, is input into a website which then is saved and the data exported to the automated knitting machine without any retyping of data.

The machine knits and knits, the garment is washed, dried, and steamed to shape and is out the door. A fully customized garment which could be, depending on sales volume, out the door and on the way to a customer in a single day. When the production flow is optimized the cost of a custom garment is very much the same as a standard mass produced garment.

I would expect within 5-10 years most clothing for middle to upper class customers will be customized. Manufacturing villages, be small and high-tech should be first in successful and profitable customization.

-

Continuing Profits

Continuing profits keep manufacturing villages in business for the long term through two channels:

Central services backoffice structures

Continual auditing of both busienss flow and production

The intention is a 95% sucess rate through startup to key person issues. If you are not in business you are not helping anyone! Successfully read on ...

Starting with good markets, desirable products for the chosen markets, most modern technology and efficient production, to choosing the right people to create the best atmosphere nothing should be left to chance or luck. The success of a manufacturing village is important to the community and the people who live there.

-

Keeping the Financial People Away from MV's

Nothing destroys a business faster than a chief executive from the financial path. Keeping the entrepreneurs in charge ...

In almost every company history from the beginning of the industrial age - that is when corporations first became possible - the finest hours of the company are when the original entrepreneur still ran the company. The next best time usually is when the entrepreneur picks an entrepeueral successor.

-

MV'sw make Employees More Efficient

Small satellite production with small workforces restrict beauracy which intrinsically means inefficiency. See the efficient article ...

When groups climb past 12 members people don't have direct contact on a daily basis. By keeping production groups small, supervisors easily see not only inefficiences, but additionally, why the inefficiency occurs. I guess you can say this is engineering by walking around.

Installing new technology - and knowing what technology is available - as well as seeing the problems incurred are obvious quickly. One of the benefits of being part of a manufacturing village, as a satellite owner/manager is you are not top of the food chain: someone in central services will either have the proper solution or know where to find an answer.

Central services, through monitoring and audits, ensures continuing efficiency which of course is exceedingly Important to profits.

-

Repurpose Malls and Buildings to New Manufacturing

No, I didn't start the stampede to repurpose old building to residential and retail, yet, small manufacturing without a pollution component is an important part of recalibrating and reconfiguring American real estate. Read more ...Manufacturing Villages can work within an rural/urban area, especially in the towns of middle America. Certainly, enough old manufacturing buildings and malls are available for reconfiguring for homes for many small businesses. In today's economy, with many millennials want to walk or take rapid transit to work instead of driving, investment is circling the old factories and malls for new opportunities.

Manufacturing Villages can exist with separate buildings in close proximity such as an industrial park or in old manufacturing facilities or old malls. Many transformations of old manufacturing buildings will look like the malls. Think about access for shipping, good electricity capabilities, food facilities, day-care facilities, and even lots of parking lots that can be rolled up to build worker housing. Several examples were recently completed in Brooklyn - check along the water on 36th St.- and the old warehouses sure look like malls.

Since Manufacturing Village businesses are small, the products they make are small, and by being fully automated limit waste and pollution, we should see many towns and communities interested in a Manufacturing Village - or two or three - to bolster the local economy and bring old non-taxpaying facilities back on the tax roles.

Once we have one Manufacturing Village example the creation of the next 100 manufacturing villages could rapidly be established.

-

Manufacture Anything You Want

The flexibility of Manufacturing Villages does not limit what can be made except for the size of the product as small sized items are much easier to handle. Products should be able to ship via UPS, Fedex, or USPS. Click here to size up the whole story...

Large products require machines to help lift and move, take up more room in the warehouse, require long sales cycles, and large production machinery. This is not condusive to keeping satellite production small and low cost. Having small satellite units help keep a more initmae feel for the manufacturing village.

Each manufacturing village should have some continuity such as a vertical market. Some satellites could produce sub-assemblies for other satellites.

While I will have a list of ideas, these are the first ones I'd like to see created.

- Custom sweaters and sweatshirts using latest automation

- For women in cold offices

- For golfers

- Kevlar garements for motorcycle riders

- Style concious customers

- Composit laminates

- Garden decorations like giant pots, waterfalls, and bridges

- Decoration for motorcycles and hot rods

- 3D printed for casting

- Jewelry for young people

- Jewelry for motorcycle people

- Wood working

And so on. It doesn't matter what is made just as long as the most modern automation is utilized, keep the product small, and sell on the internet directly to customers. Wholesale is a secondary channel.

-

MV's Geared for Training

Training new employees, whether in a school situation or on-job training always remains a necessity. Read how manufacturing villages will pay for training...

Bigger companies will hire well-trained people away from Manufacturing Villages. To help pay for continual training Manufacturing Villages will act as an employment agency for these biger companies and receive a fee. Training should not be free for the bigger companies: Manufacturing Villages are not here to increase the profits of the companies wanting our employees. Employees will work under contracts that when hired away from the manufacturing village we charge an employment fee to pay for the training of the people the bigger companies need and don't have time to train.

It's actually a pretty good deal for everyone.

-

Repository for New Technology

Whether back office operations or manufacturing operations a library of new and available technology is important. Just the amount of new technology in the engineering magazines requires a full time researcher to list and document what new products and processees are available for implementation. Learn about our library....

If anyone cares to read the journals I receive please be my guest. I have suggested to business schools to have an entire semester class about reading technical magazines. Of course, the schools don't want to be bothered by reality. Without engineering journals, especialy ones dedicated to manufacturing like "Assembly" or "Quality" and more general jopurnals such as "NASA Tech Briefs" no on can keep up with what is currently available. And if you think you have trouble going through all your emails, just add in "ENC" and "Sourcing Journal".

One of the reasins to have a non-profit wing, ManufacturingVillage.org, is ceating a database of manufacturing technology and a newsletter to get what's new out to Manufacturing Village members. The non-profit will also generate videos and other educational stuff.

-

Small Manufacturng Good for Incorporating New Technology

Manufacturing Village producers are small enough to incorporate new technology with minimum expense and planning. See saving money for everyone ...

Central Services maintains a technology department just to keep everyone up to date on efficiency and cost of production. Changing the technology in a company doing under $10 Million is a different animal than $100 million production line. This makes us a good place for experimenting and testing. Possibly the manufacturing villages could make money providing testing for the bigger companies.

One advantage of having many manufacturing villages serves to try new technology in one and thten transfer the tested version to the others.

|

|